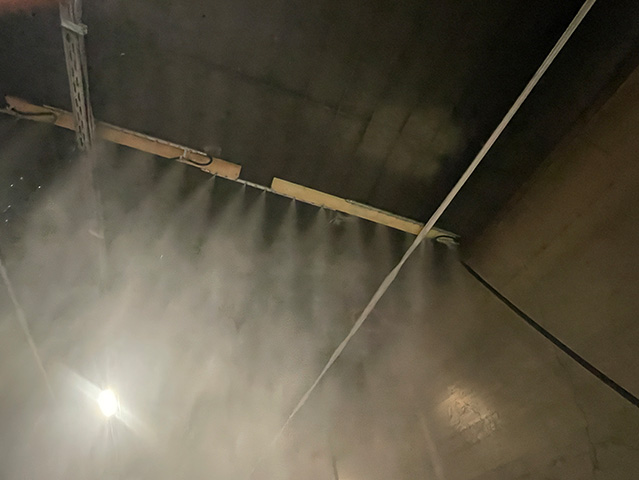

Dust binding in the tunnel

Dust binding in the tunnel

Asphalt milling work in the Vorarlberg tunnel

Tunnels are important traffic routes. These also need to be maintained and renovated if necessary.

Major players, medium-sized companies and small businesses in the field of tunnel construction / tunnel renovation from Germany, Austria and Switzerland work hand in hand. During the renovation of the Vorarlberg tunnel, the companies needed effective dust control. This was a requirement of the authorities and had to be complied with.

Due to time pressure, two asphalt milling machines were used simultaneously to remove the concrete surface. The amount of dust was enormous. A hydro shield to create large water curtains put the entire tunnel under water and was therefore not a solution.

In order to contain the dust and ensure work safety in the tunnel, they relied on the effective, reliable water misting system from NEBOLEX Umwelttechnik GmbH. With our systems, the water input can be precisely adjusted by means of a control system and is in the per mille range.

After a test set-up, which achieved the desired effect, the system was permanently installed. Individual spray fog bars with integrated mist heads were installed as water locks on the ceilings throughout the tunnel. These barriers do not allow dust to escape. Our 20 bar system atomizes the water so finely that even small particles are bound. The volatile dust absorbs moisture, becomes heavy, sinks to the ground and moistens the traffic routes. This means that no additional dust is stirred up when the vehicle is driven over.

Dust binding through water mist in recycling operations

Dust binding in recycling operations

Processing of A1 to A4 class shredded wood

In recycling plants that process shredded wood of classes A1 to A4 for waste incineration, the safety of the working environment is paramount. The use of water mist to reduce dust has proven to be an effective method of reducing dust exposure and minimizing potential risks to employees.

During the processing of shredded wood, various processes such as shredding, screening and transportation are carried out, which can release dust. This dust not only affects the working environment, but also poses health risks if it is inhaled. This is where dust minimization using water mist comes in: The finest mist is sprayed through special nozzles into the affected areas, whereby the nozzles are precisely positioned to optimally counteract the dust sources.

The water mist adheres to the dust particles and increases their weight. This causes the particles to become heavier, sink to the ground and can therefore no longer be whirled up so easily. Balanced dosing of the water mist is of central importance to ensure effective dust binding without soaking the material unnecessarily. This balance is particularly relevant for subsequent combustion, as a dry material requires less energy input.

Checking and monitoring the water mist system ensures that it functions optimally. It is essential to adjust the water quantity, spray pressure and nozzle parameters to the individual requirements of the recycling plant. Regular inspections and maintenance of the systems ensure that the system works perfectly and that the water mist is distributed efficiently.

Training employees in the correct use and handling of the water mist system is recommended to ensure maximum safety and effectiveness. The targeted use of water mist not only minimizes health risks for employees, but also creates optimal working conditions. This proven method of minimizing dust therefore makes a significant contribution to increasing safety and efficiency in recycling plants.