Dust binding - opencast mining and crusher fogging

Dust binding with water mist

Opencast mining and crusher fogging

The manufacture of various products, such as paving stones or block steps, in a natural stone factory is associated with considerable dust generation. The company was obliged by the authorities to reduce dust emissions to a minimum during the open-cast mining work and processing of the material. To prevent further inconvenience, Nebolex Umwelttechnik GmbH was commissioned to bind the dust.

After an on-site inspection and careful planning, the practical implementation began. During the demolition (blasting), several mobile dust binding machines were used to prevent the dust from spreading in the quarry. Dust binding during the further processing of the material in the crusher was ensured by spray bars attached directly to the dust source. The robust design of the stainless steel strips with integrated mist nozzles also allows them to be used in harsh environments. The nozzle technology used can easily nebulize dirty water, i.e. screened surface or cistern water. Neither small impurities nor a high lime or salt content pose a problem for dust precipitation.

Dust control - ceiling foggers in halls

Dust binding - Ceiling fogger

Water atomization in halls to reduce dust

A company based in south-eastern Baden-Württemberg has been manufacturing products for the timber industry for several generations. During the shredding process and further processing, a considerable amount of dust of recyclable material classes A1 and A2 is produced.

To ensure work safety, several ceiling foggers were installed to reduce dust. These misting devices are attached to the hall ceiling and spray a fine mist of water. This increases the humidity, causing the dust particles suspended in the air to combine with the water mist and sink to the floor. This keeps the hall floor damp, which also prevents dust from being stirred up by moving vehicles in the hall. The amount of water added is minimal and is precisely controlled to avoid the formation of puddles.

In areas where waste material generates a lot of dust due to its high drop height on the conveyor belt and visibility was severely restricted at times, additional spray bars were installed to prevent accidents.

The targeted use of water mist protects employees from health risks and the company enjoys a good relationship with its neighbors.

Odour binding Introduction of additives for neutralization

Odour binding - neutralization through additives

Mobile machines from NEBOLEX Umwelttechnik

Odour control is the introduction of additives to neutralize unpleasant odours using mobile machines or stationary systems. Most of us take our sense of smell for granted and only notice it when a particularly pleasant smell or an unpleasant odor catches our attention. This difference in the perception of our sense of smell is well known. But in certain work environments, especially waste disposal facilities, foul odors can become a serious nuisance.

When kitchen waste, food scraps or silage come into contact with moisture and heat, a decomposition process begins that leads to foul odors. The butyric acid and hydrogen sulfide released in the process can lead to extreme odor nuisance. Unfortunately, there is often little understanding and acceptance of this problem in the immediate vicinity. The poor air quality has a significant impact on daily life, which presents the affected companies with the challenge of finding an effective and economical solution.

Our main objective is to develop measures to improve the odor situation in industrial plants in the long term and to comply with the threshold values in odor-intensive production areas. Our solution is based on the use of water mist and a special additive to bind odors. This nebulization system is particularly efficient for composting and recycling solid and liquid materials.

The neutralizing additive is added to the nebulized water via a dosing unit. The resulting solution in the form of a light spray mist remains suspended in the air, enveloping and binding the unpleasant odor molecules immediately and permanently. The result: no more unpleasant odors and no more puddles of water.

The choice of a suitable system, be it a single- or dual-substance system or a mobile dust binding machine, depends on the individual needs, requirements and expectations of the operator. In most cases, a personal on-site visit with a consultation is required to explain the advantages of the various systems.

Odor control plays a crucial role in the well-being of employees in the workplace. A pleasant working environment significantly boosts employee satisfaction and productivity.

Dust binding belt discharge with water spraying

Screen misting

Water spraying on a discharge conveyor.

In a quartz plant in the northern part of Rhineland-Palatinate, we were faced with the challenge of minimizing dust turbulence and reducing the environmental impact. Here, rock is extracted from a quarry pond and then transported to a crusher using wheel loaders. The crushing and discharge of the crushed sand of grain size 0-2 led to considerable dust formation.

The basic cube, a semi-mobile supply unit from NEBOLEX, was used for the test setup. During test runs with fresh water, the system technology not only convinced the authorities, but also our customer. The system was later installed with a special filter technology that uses process water.

Material is fed in sporadically by the wheel loader and water spraying is controlled by ultrasonic sensors. As soon as the wheel loader passes the barrier, the fogging process starts at the crusher for a preset time. The start, water input and fogging time are precisely monitored and controlled.

The targeted use of water mist not only protects your employees, but also the environment and nature.

Dust binding in the tunnel

Dust binding in the tunnel

Asphalt milling work in the Vorarlberg tunnel

Tunnels are important traffic routes. These also need to be maintained and renovated if necessary.

Major players, medium-sized companies and small businesses in the field of tunnel construction / tunnel renovation from Germany, Austria and Switzerland work hand in hand. During the renovation of the Vorarlberg tunnel, the companies needed effective dust control. This was a requirement of the authorities and had to be complied with.

Due to time pressure, two asphalt milling machines were used simultaneously to remove the concrete surface. The amount of dust was enormous. A hydro shield to create large water curtains put the entire tunnel under water and was therefore not a solution.

In order to contain the dust and ensure work safety in the tunnel, they relied on the effective, reliable water misting system from NEBOLEX Umwelttechnik GmbH. With our systems, the water input can be precisely adjusted by means of a control system and is in the per mille range.

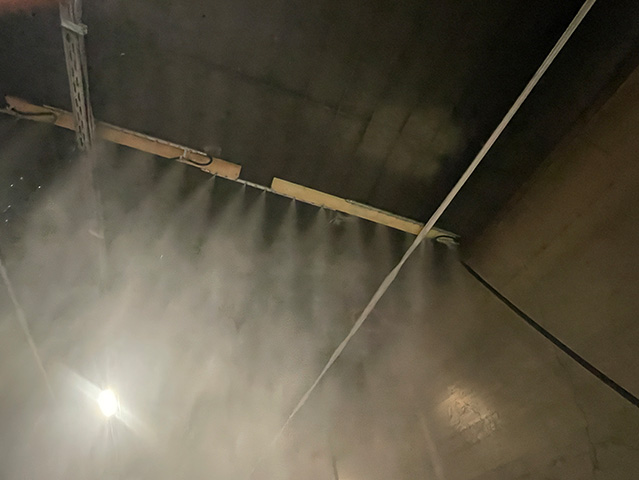

After a test set-up, which achieved the desired effect, the system was permanently installed. Individual spray fog bars with integrated mist heads were installed as water locks on the ceilings throughout the tunnel. These barriers do not allow dust to escape. Our 20 bar system atomizes the water so finely that even small particles are bound. The volatile dust absorbs moisture, becomes heavy, sinks to the ground and moistens the traffic routes. This means that no additional dust is stirred up when the vehicle is driven over.

Dust binding through water mist in recycling operations

Dust binding in recycling operations

Processing of A1 to A4 class shredded wood

In recycling plants that process shredded wood of classes A1 to A4 for waste incineration, the safety of the working environment is paramount. The use of water mist to reduce dust has proven to be an effective method of reducing dust exposure and minimizing potential risks to employees.

During the processing of shredded wood, various processes such as shredding, screening and transportation are carried out, which can release dust. This dust not only affects the working environment, but also poses health risks if it is inhaled. This is where dust minimization using water mist comes in: The finest mist is sprayed through special nozzles into the affected areas, whereby the nozzles are precisely positioned to optimally counteract the dust sources.

The water mist adheres to the dust particles and increases their weight. This causes the particles to become heavier, sink to the ground and can therefore no longer be whirled up so easily. Balanced dosing of the water mist is of central importance to ensure effective dust binding without soaking the material unnecessarily. This balance is particularly relevant for subsequent combustion, as a dry material requires less energy input.

Checking and monitoring the water mist system ensures that it functions optimally. It is essential to adjust the water quantity, spray pressure and nozzle parameters to the individual requirements of the recycling plant. Regular inspections and maintenance of the systems ensure that the system works perfectly and that the water mist is distributed efficiently.

Training employees in the correct use and handling of the water mist system is recommended to ensure maximum safety and effectiveness. The targeted use of water mist not only minimizes health risks for employees, but also creates optimal working conditions. This proven method of minimizing dust therefore makes a significant contribution to increasing safety and efficiency in recycling plants.